Your cart is currently empty!

Energy-Efficient Bricks: Reducing Landfill Waste and Cutting Energy Costs

Image: RMIT reasearch team with team leader Associate Professor Dilan Robert (thrid from left). Credit: Seamus Daniel.

Engineers from RMIT University have teamed up with Visy, Australia’s largest recycling company, to develop bricks containing at least 15% waste glass and 20% combusted solid waste (ash) instead of clay.

Tests reveal that incorporating these bricks into the construction of a one-story building may lead to a 5% reduction in household energy expenses compared to traditional bricks, thanks to enhanced insulation.

Substituting clay with waste components during brick manufacturing slashed firing temperatures by as much as 20% compared to conventional brick blends, presenting promising cost-cutting opportunities for producers.

Associate Professor Dilan Robert, the team leader, stated that approximately 1.4 trillion bricks are utilised annually in construction projects worldwide.

“Conventional brick production results in detrimental emissions, such as carbon dioxide, sulphur dioxide, and chlorine, and imposes significant pressure on our natural resources, particularly clay,” explained Dilan, hailing from RMIT’s School of Engineering.

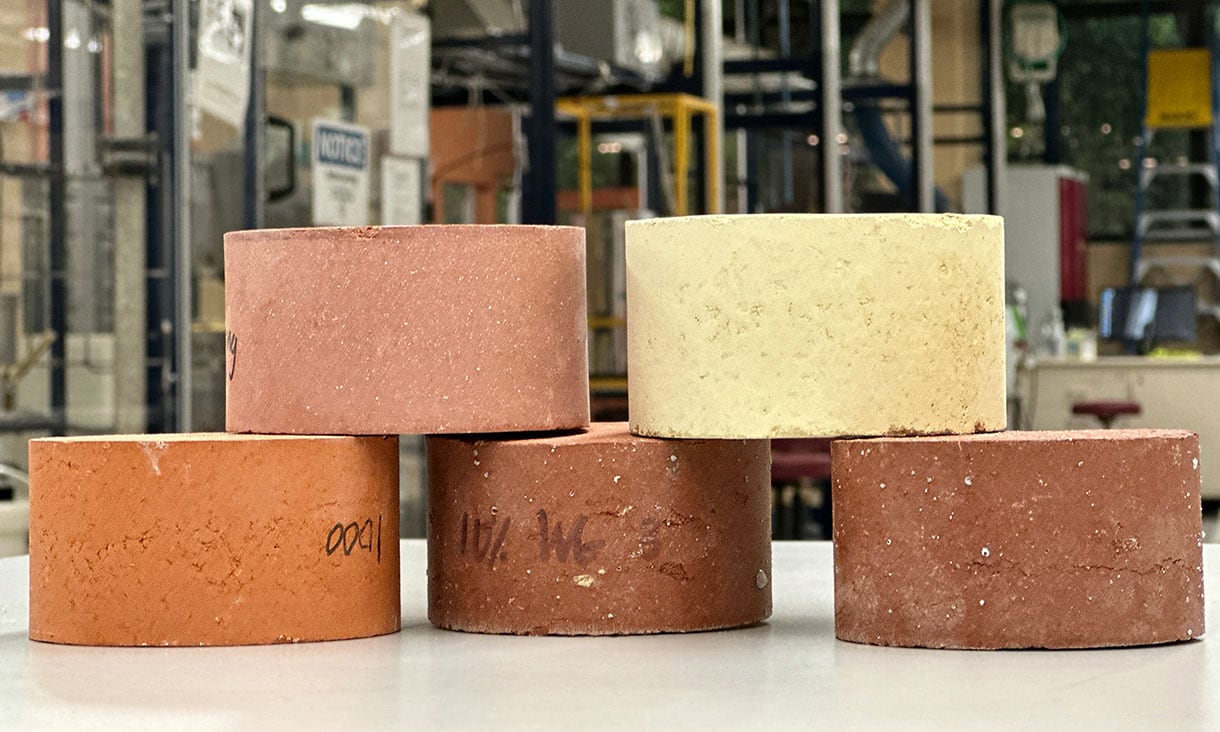

Image: Bricks can be created in a range of different colours.

The team’s most recent research has been published in the international journal Construction and Building Materials.

The team’s investigation revealed that the new bricks exhibit improved energy efficiency due to enhanced thermal performance and adhere to rigorous standards for structural integrity, durability, and environmental sustainability.

This technology fulfills the primary compliance criterion for fired clay bricks established by Standards Australia (AS 3700).

“Bricks play a key role in preventing energy loss from buildings,” Robert said.

“We can also produce light-weight bricks in a range of colours from white to dark red by changing our formulations.”

Dr Biplob Pramanik, the RMIT team’s environmental engineer, said the new bricks were safe to use in construction projects.

“Our bricks, manufactured from industry waste, meet state environmental regulations,” he said.

Image: Ash used in the production of energy-smart bricks.

In Victoria, Visy specialises in recycling glass packaging into new bottles and jars. However, glass fragments smaller than 3mm, known as fines, are ineligible for bottle recycling.

“We are focusing on scaling up the production process to facilitate the commercialisation of our innovative bricks in collaboration with brick manufacturers in Melbourne,” Robert said.

Paul Andrich, Visy’s Innovation Project Manager, expressed enthusiasm about discovering a solution for materials unsuitable for recycling into food and beverage packaging.

“Diverting this waste into bricks with added insulation, rather than landfill, is another way we are powering the circular economy,” he said.

The research team aims to collaborate with industries to investigate the utilisation of waste materials in other construction products.

The RMIT team has published peer-reviewed research on the brick innovation in several journals.

‘Utilizing rejected contaminants from the paper recycling process in fired clay brick production’ is published in Construction and Building Materials.

‘Energy efficiency of waste reformed fired clay bricks – from manufacturing to post application‘ is published in the journal Energy.

‘A viable solution for industrial waste ash: Recycling in fired clay bricks‘ is published in the Journal of Materials in Civil Engineering.

‘Transformation of waste-contaminated glass dust in sustainable fired clay bricks‘ is published in Case Studies in Construction Materials.